Wazzup Pilipinas!?

The Netherlands and Taiwan stand at the vanguard of the #CircularShift—transforming discarded plastics into engineering marvels, textile waste into high-fashion fabrics, and battery remnants into digital passports for a sustainable future.

This isn't just recycling. This is reimagining the very DNA of industry itself.

From Rotterdam to Taipei, pioneers are rewriting the rules: where lettuce grows without soil and waste, where electric vehicle batteries gain second lives through transparent traceability, where yesterday's ocean plastics become tomorrow's premium materials. Companies aren't just reducing their footprint—they're erasing the very concept of waste.

The challenge is global. The innovation is Dutch. The partnership is unstoppable.

These aren't distant dreams or corporate greenwashing. These are operational realities—proven technologies, scaling solutions, and a collaborative ecosystem connecting knowledge institutions, governments, and industry leaders across continents.

The circular economy isn't coming. It's here. And it's being built by those bold enough to see opportunity where others see only trash.

Join the movement. Make the #CircularShift. Because in the economy of tomorrow, nothing is wasted—everything is transformed.

In a world drowning in disposables, a revolution is rising from what we once threw away. The Netherlands and Taiwan stand at the vanguard of the #CircularShift—transforming discarded plastics into engineering marvels, textile waste into high-fashion fabrics, and battery remnants into digital passports for a sustainable future.

This isn't just recycling. This is reimagining the very DNA of industry itself.

From Rotterdam to Taipei, pioneers are rewriting the rules: where lettuce grows without soil and waste, where electric vehicle batteries gain second lives through transparent traceability, where yesterday's ocean plastics become tomorrow's premium materials. Companies aren't just reducing their footprint—they're erasing the very concept of waste.

The challenge is global. The innovation is Dutch. The partnership is unstoppable.

These aren't distant dreams or corporate greenwashing. These are operational realities—proven technologies, scaling solutions, and a collaborative ecosystem connecting knowledge institutions, governments, and industry leaders across continents.

The circular economy isn't coming. It's here. And it's being built by those bold enough to see opportunity where others see only trash.

Join the movement. Make the #CircularShift. Because in the economy of tomorrow, nothing is wasted—everything is transformed.

Holland Circular Hotspot (HCH)

"The Global Nerve Center of Circular Revolution"

They are the matchmakers of sustainable transformation. Holland Circular Hotspot doesn't just connect companies—they architect entire ecosystems where circular innovation thrives. From Dutch pioneers to international changemakers, HCH bridges the gap between groundbreaking ideas and global implementation. They're not observers of the circular economy; they're the conductors orchestrating its worldwide symphony, turning isolated innovations into collaborative movements that reshape industries and redefine what's possible.

BNL Supplies B.V.

"Giving Batteries a Second Heartbeat"

In a world racing toward electrification, BNL Supplies asks the question everyone else ignores: What happens after? They've cracked the code on lithium battery immortality—repairing, recycling, and creating digital passports that track every battery's journey from cradle to rebirth. Operating across Asia and Europe, they're not just servicing e-bikes and yachts; they're building the infrastructure for a future where batteries never truly die. By 2027, their Battery Passport Platform will make every cell traceable, accountable, and endlessly renewable. They're not managing waste—they're manufacturing permanence.

Rijk Zwaan

"Feeding the Future Without Wasting the Earth"

For over a century, Rijk Zwaan has been engineering the seeds of tomorrow. With 30+ crop categories and 2,000+ varieties serving 100+ countries, they're not just growing vegetables—they're cultivating a revolution in sustainable agriculture. Their innovations enable farmers to produce crystal lettuce and vibrant greens using 50% less water, while their breeding magic creates produce that meets diverse regional tastes and climates. Through continuous R&D, they're proving that feeding a growing planet and protecting it aren't opposing goals—they're the same mission, one seed at a time.

MVRDV

"Architecture That Imagines Cities Reborn"

Since 1993, MVRDV has been designing more than buildings—they've been prototyping the future. With 300+ visionaries across Rotterdam, Shanghai, Paris, Berlin, and New York, they tackle urban challenges with research-driven boldness. From Rotterdam's Markthal to Amsterdam's Depot Boijmans Van Beuningen, their projects breathe new life into cities while their MVRDV NEXT technology unit and Carbon Scape software integrate sustainability into every beam and blueprint. Their collaboration with The Why Factory doesn't just reduce environmental impact—it envisions cities where innovation and sustainability aren't features, but foundations. They're not building for today. They're constructing tomorrow's urban dreams.

Dijmex

"Where Plastic Waste Becomes Engineering Excellence"

Founded in 1938 as a family business, Dijmex has spent 87 years perfecting the art of transformation. They take post-consumer and industrial plastic waste and metamorphose it into high-grade engineering materials that power automotive, electronics, and manufacturing sectors worldwide. Processing varieties like ABS, PA, PC, and PC/ABS with low-carbon precision, they don't just recycle—they upgrade. Every pellet undergoes rigorous laboratory testing, ensuring stability, performance, and full traceability. Their vision? "GREEN & GREAT." Their reality? Turning the Netherlands' plastic problem into premium solutions, proving that waste isn't an endpoint—it's raw potential waiting to be unleashed.

NoMilk2Day

"Recruiting the Circular Workforce of Tomorrow"

The circular economy needs more than technology—it needs talent. Since 2015, NoMilk2Day has been the bridge connecting agricultural, food, and industrial innovators with the professionals who will lead the transformation. Operating across Asia, the U.S., and Europe, with Taiwan expansion launching in 2025, they specialize in executive search, management recruitment, and remote talent solutions for the Northeast Asian market. They don't just fill positions; they forge connections that accelerate the shift to sustainability. By participating in international trade shows and fostering passion-driven recruitment, they're ensuring the circular economy has the human capital to match its ambition. They're not headhunters—they're revolution builders.

ReBlend

"Textile Waste's Second Act Starts Here"

Founded in 2014 by Anita de Wit, ReBlend is rewriting the fashion industry's wasteful script. This multi-expertise network transforms discarded textiles—denim, knits, furniture fabrics—into high-quality yarns and materials that rival virgin cotton. Through collaboration with designers, producers, and knowledge institutions, ReBlend has pioneered innovative reuse strategies and co-creation projects that reduce environmental impact across the entire textile chain. Over the past decade, they've proven that textile waste isn't trash—it's treasure waiting for creative minds to unlock. From cotton recycling to circular alternatives, ReBlend doesn't follow fashion trends. They create sustainability movements that make waste obsolete.

Siebtechnik Tema B.V.

"Separation Science Meets Zero Waste Ambition"

Siebtechnik Tema B.V. is the unsung hero of the circular economy—the technology that makes everything else possible. As a global leader in advanced separation and process technology, they provide the critical infrastructure for plastics recycling: high-quality screening, centrifuging, and drying systems. But their true innovation? Zero Liquid Discharge (ZLD) technology. Their decanters, centrifuges, and filtration systems minimize industrial wastewater while recovering valuable resources globally. Aligned with UN Sustainable Development Goals (SDGs), Siebtechnik Tema's technologies don't just reduce waste—they make resource recovery efficient and sustainable. Through innovation and global presence, they're proving that what we separate today determines what we save tomorrow.

Tible BV

"Making Recycling Intelligent, Transparent, and Unstoppable"

Tible is the Dutch tech company turning recycling from a chore into a smart, seamless experience. Their innovative platforms—Deposit Return Systems (DRS), Reverse Vending Machines (RVM), and recycling processes—are deployed worldwide, empowering resource reuse and circular thinking. Their flagship products, HAWK and the Reverse Vending Collector (RVC), deliver data management, automation, and integration across complex value chains with military-grade security and compliance. Tible helps retailers, producers, and system operators boost efficiency, ensure transparency, and meet sustainability goals aligned with international regulations. At Tible, recycling isn't everyone's daily choice—it's their permanent solution. They're building the digital backbone of the circular economy, one transparent transaction at a time.

Together, these organizations aren't just participants in the circular economy—they're the architects, engineers, and visionaries making it inevitable.

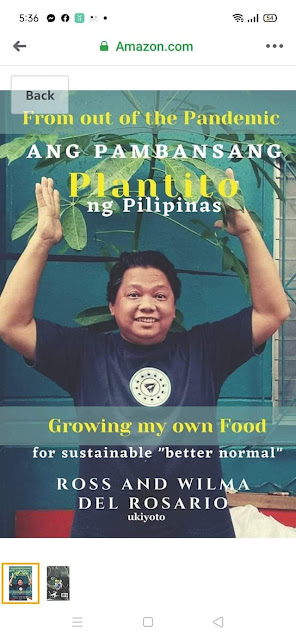

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

.jpg)